Research Focus

Research field

Detailed research areas and business areas

Topic 3: Development of High-Reliability Automotive Semiconductor Bonding Materials

Research Task 1

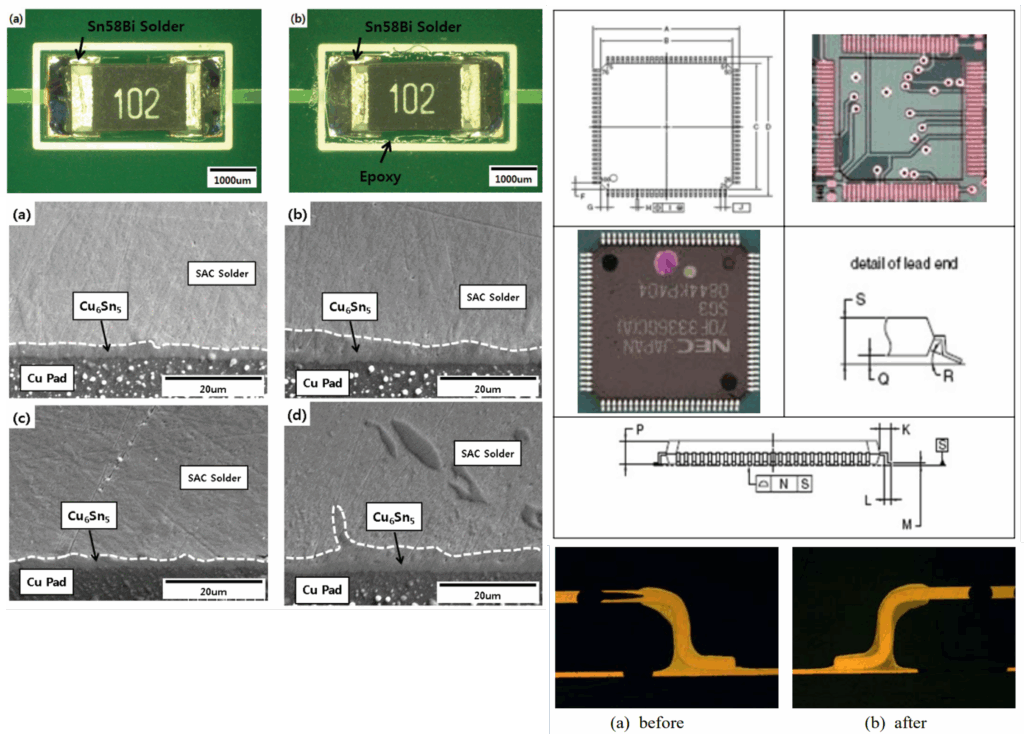

Solder joint reliability assessment

-

Measuring joint strength through shear, tensile, and bending tests

-

Analysis of stress concentration and crack initiation due to rapid temperature changes (e.g. -55 ℃ ↔ +125 ℃)

-

Evaluation of fatigue crack occurrence due to coefficient of thermal expansion (CTE) mismatch of solder joints in high and low temperature repeated environments

-

Comparison with life expectancy prediction models (Coffin-Manson, Engelmaier, etc.)

-

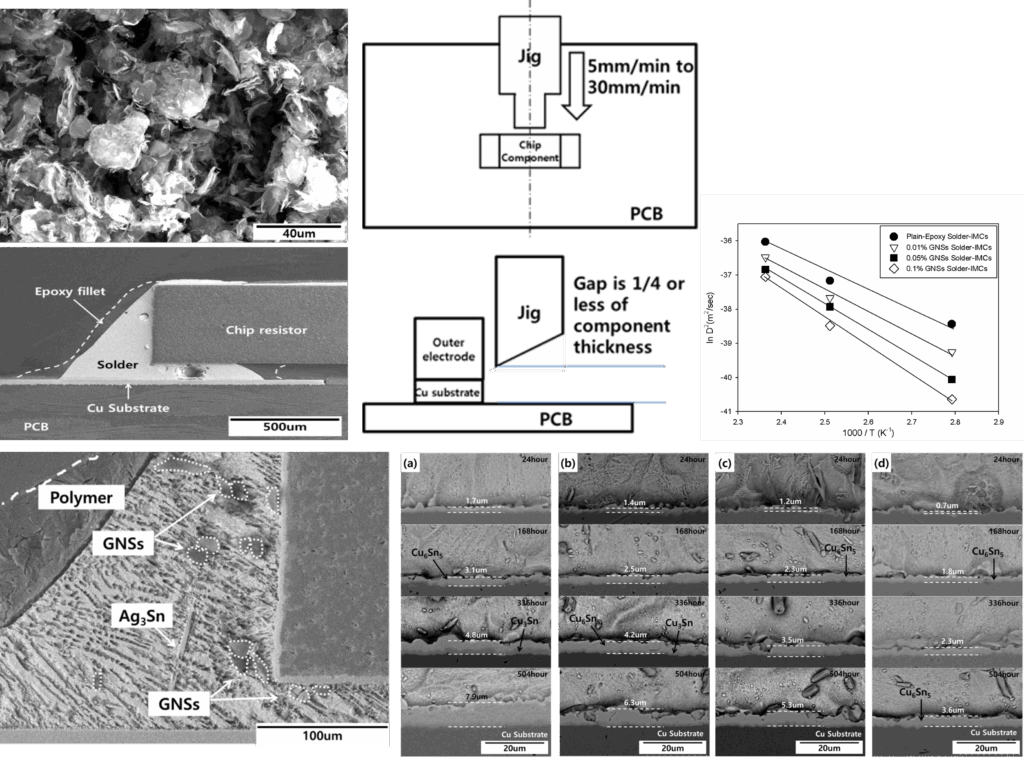

Analysis of IMC (Intermetallic Compound) Growth Behavior Using Scanning Electron Microscopy (SEM), TEM, and FIB

-

Observation of intermetallic compound layer thickness, crack/void distribution, and grain boundary cracking

Research Task 2

Development of high-performance solder and bonding materials

-

Development of bonding materials for eco-friendly electronic products and compliance with RoHS/REACH regulations

-

Development of high-temperature solder for automotive and power semiconductor applications, capable of operating at temperatures above 200°C.

-

Development and evaluation of nano-reinforced solders

-

Development of high-heat dissipation bonding materials (Thermal Interface & High-conductivity Materials)