Research Focus

Research field

Detailed research areas and business areas

Topic 1: Research on the Development and Characteristic Evaluation of Composite Materials for Mobility

Research Task 1

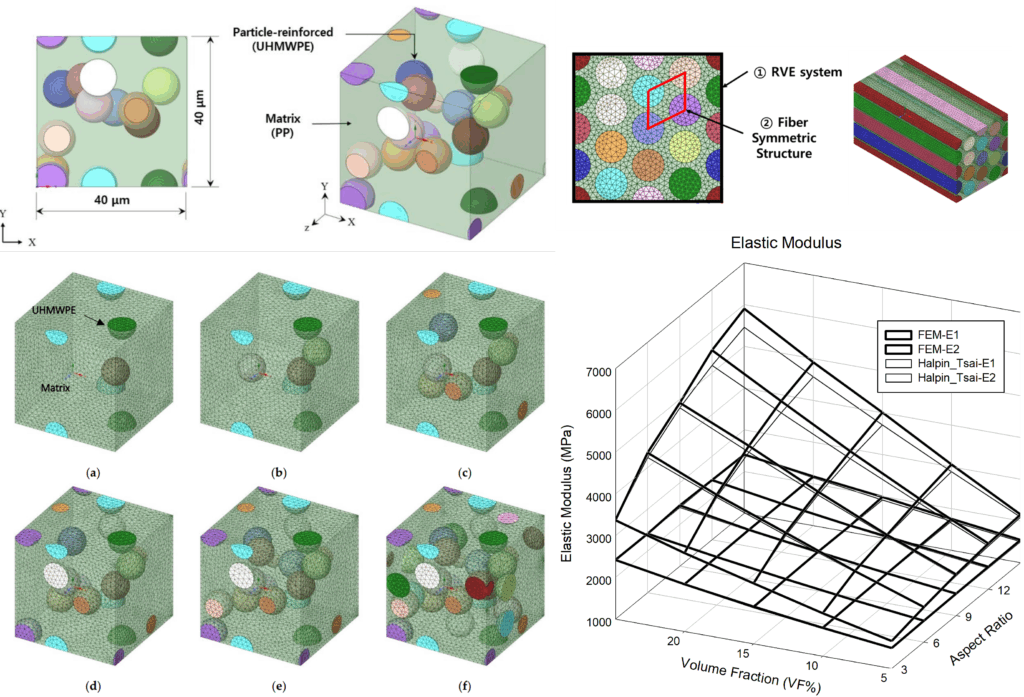

Analysis of effective properties of composite materials through simulation

-

Effective material property analysis through simulation to analyze the behavior and performance of composite materials.

-

Finite element analysis (FEM) using ANSYS, multi-scale analysis based on Digimat

-

Systematic evaluation of effective mechanical and thermal properties of composite materials

-

The reliability of the simulation-based material property prediction results is ensured through cross-validation with actual experimental data.

-

Expanding into application areas such as optimal design of high-performance composite materials, development of lightweight structural components, and ensuring thermal reliability.

Research Task 2

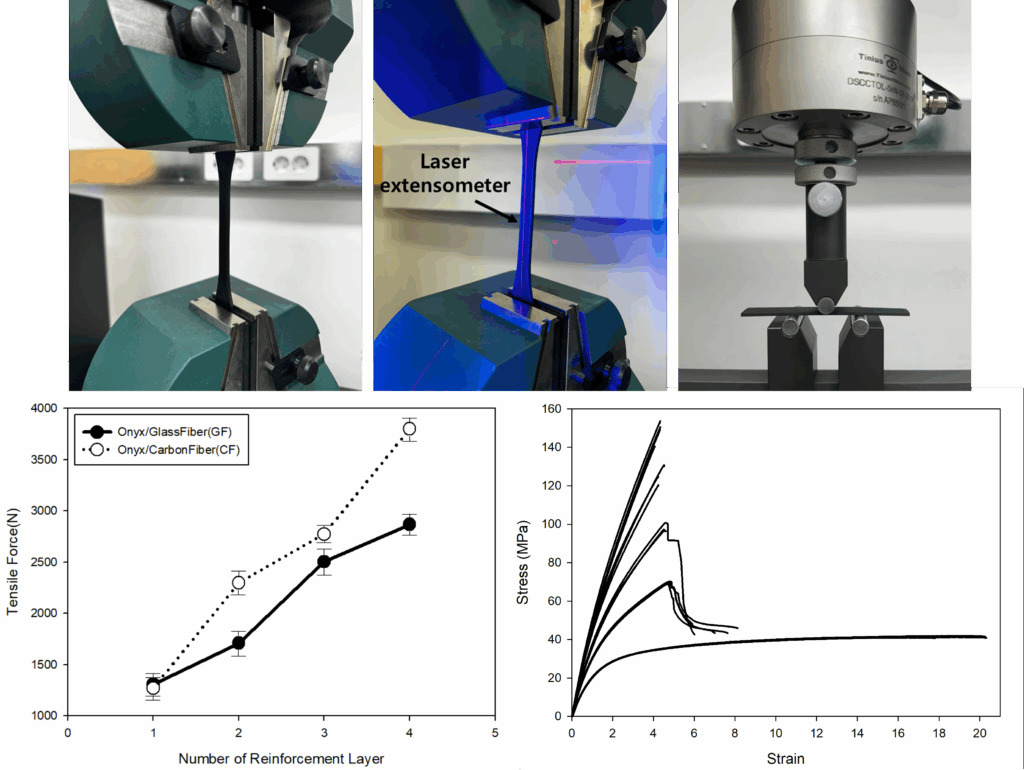

Characteristic evaluation for manufacturing composite materials and securing basic properties

-

Direct manufacturing of particle-reinforced, fiber-reinforced, and woven-based reinforced composites

-

Identify basic mechanical properties such as strength, elastic modulus, and ductility through mechanical tests such as tensile tests, bending tests, and compression tests.

-

Securing a database of basic properties of composite materials and establishing correlations between manufacturing process, microstructure, and properties.

-

Utilized as key data for optimizing the structural design of composite materials, ensuring reliability, and developing lightweight, high-performance materials for mobility.

Research Task 3

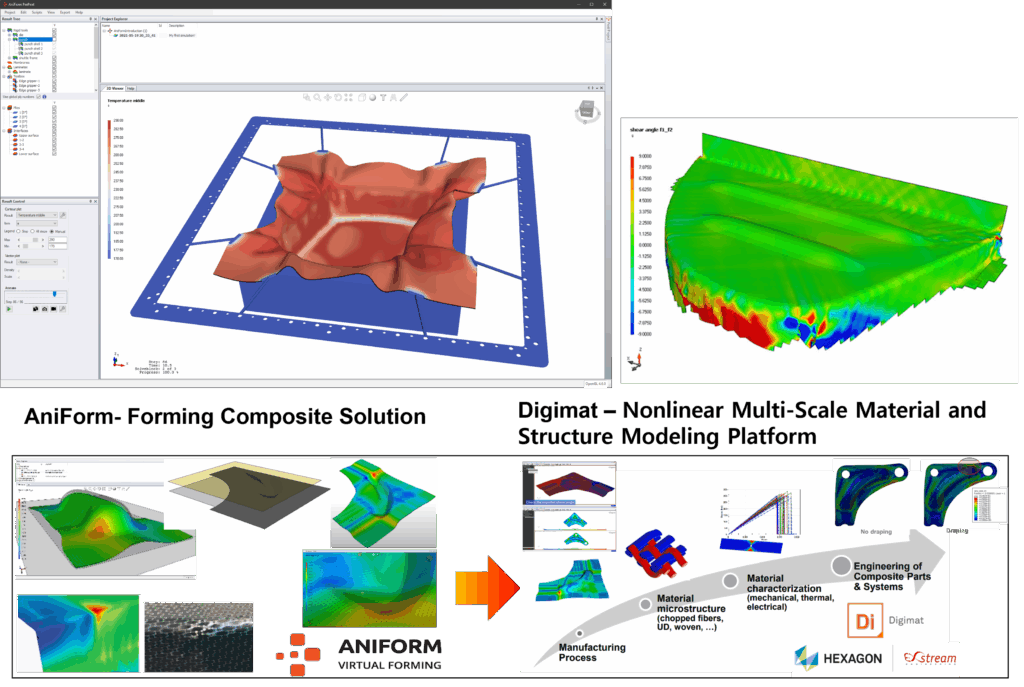

Composite material molding processability evaluation and mass production review

-

Quantitatively evaluate the formability of composite materials and examine their applicability in actual manufacturing processes.

-

Finite element analysis (FEM) based on Aniform can predict problems such as wrinkles, fiber distortion, and thickness non-uniformity that may occur during actual molding by considering fiber orientation, material nonlinear behavior, and interface friction conditions.

-

Validation of the results by conducting small-scale molding experiments in parallel with simulation-based analysis.

-

Preliminarily review the possibility of mass production of composite materials and provide efficient design and manufacturing guidelines that consider industrial applicability from the material development stage.